|

|

Post by Nick Basile on Jan 21, 2018 17:59:15 GMT

I just got my Pro Edge andI also have been strugaling with wanting to duplicate Stuart Batty's 40 x 40 bowl gouge grind and was disappointed with the lack of information that comes with the pro edge. I was able to get close using my Tormek with some settings shown in my Tormek book. I wanted to retire my Tormek as it is slow. However it just occurred to me that if I use a 5/8" wooden dowel with a rounded groove routed in the middle, I can replicate the grinds on a bowl gouge without the expense of destroying a tool. Because the pro edge uses abrasive belts that will cut wood easily, unlike any other wheel grinder. I can experiment with all the controls and have a quick and cheap result which I can then catalog. I plan to start this experiment very soon. I have also come up with a much faster way to take the guard on and off. Are you listening Sorby? the Pro Edge has the potential to become the premier tool grinder among turners. You are 90% there. Tormek is a GREAT System but is slow. CBN Wheels with a wolverine jig are great but unless you want to change out wheels all the time you are stuck with two grits. The pro edge could change bench grinding norms if you could do just a bit more to make it address customer needs. You need a catalog of grinds at a great many settings and a quick way to remove the guard. If you need help please let me know. You know we Americans are always more than happy to help our British cousins. We owe you for all the great Masterpiece Theatre over the years.

|

|

|

|

Post by Pete on Jan 21, 2018 18:51:47 GMT

Word of caution, wood dust and sparks don't go well together. I have also used wood to practice grind angles but be sure to clean the saw dust up before making sparks.

|

|

|

|

Post by Joe o connor on May 7, 2018 16:13:29 GMT

Could someone please just tell me what number the arrow should be set to, as I moved mine,and the ring setting, I can't find anything on video, thanks

|

|

|

|

Post by Robert on May 8, 2018 10:03:13 GMT

Hi Joe

As a guest I can't message you so please send me an email address to sales@robert-sorby.co.uk I will forward you the instruction.

I look forward to hearing from you

|

|

|

|

Post by phoneman on Jun 3, 2018 7:23:05 GMT

I think it is regrettable that Sorby went to the trouble of designing a good machine and has not invested in improving it. Sorby uses the older model Tormek gouge jig. It was the state of the art at the time, however, Tormek replaced it a while back, long enough ago that Sorby should have switched. The new Tormek jig is much improved.

The gouge jig is a very versatile tool. In skilled hands it can create a wide range of profiles which are easily repeatable. Repeatability means not only faster sharpening, but also removing a minimum of steel. Without a proper handbook and/or instruction video, this fine jig is hobbled. A user could do this for himself with a couple of matching gouges. Start by sharpening one of the gouges to the 0 setting. Make a simple photo of the gouge edge. Your phone or tablet camera can do this. Include a piece of paper with the jig settings. You could do this with every jig setting number, however, every other number (0,2,4,6) will give the idea. Observe the differences. I would also include a photo of the factory grind. For the gouges you use for turning, make labels for the gouge itself.

This exercise will help you learn gouge sharpening. You still must learn the grinding technique, however, you will understand the jig, a giant step forward.

I still think Sorby should produce proper training aids.

phoneman

|

|

|

|

Post by akshayv on Jun 12, 2018 13:01:50 GMT

I had a very severe bout with plantar fasciitis. Had to have injections etc. and my orthotics were painful to wear. With my orthofeet there is no need for the orthotics and I can walk again free from pain. I balked a little over the price but freedom from pain is worth every penny spent.

|

|

|

|

Post by sorbysharp on Mar 10, 2019 7:11:32 GMT

Sorry to resurrect an old thread, but I could use some quick, straightforward answers to a basic question. I will be giving a demonstration using a Sorby turning tools set. There will be a Sorby ProEdge with the fingernail Profiler, but they won't have a Sorby Angle Set. I have my own personal Tormek TTS-100 setter that I could bring to the demonstration. Sorby Angle Set: www.robert-sorby.co.uk/sharpening/proedge/proedge-accessories/wproset-proedge-angle-setTormek TTS-100: www.tormek.com/international/en/accessories/other-accessories/tts-100-turning-tool-setter/-> I need to know the Sorby-recommended distances from its Angle Set setter jig. Please help. Here are my questions: * Are the setting distances the same for the Tormek TTS-100 and the Sorby Angle Set? SPECIFICALLY: Is the Sorby 45 degree length the same as the 65 mm setting on the Tormek TTS-100? * If not, what are the lengths for the Sorby Angle Set? (I really need that 45 degree length, please!) I don't care if they are metric or imperial, as long as they are correct and accurate. Please help! Thanks. |

|

|

|

Post by Pete on Mar 10, 2019 11:44:09 GMT

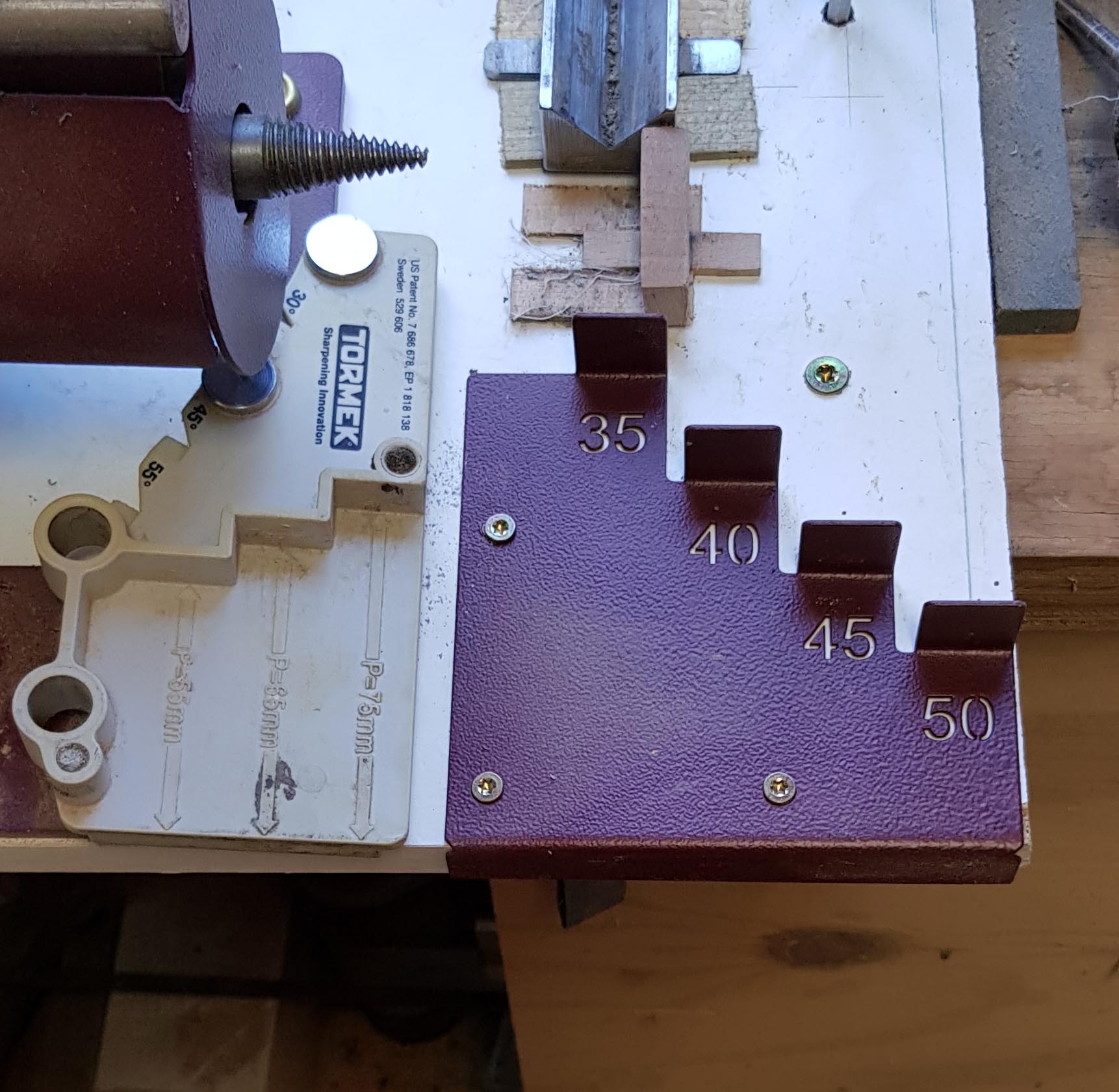

As you can see from the picture they are quite different. I measured with my digital vernier, so while I am sure you can round the numbers, and my gauge is not the most expensive one! I will say exactly what it said... Degrees Distance

50 45.82mm

45 64.12mm

40 86.32mm

35 113.52mm |

|

|

|

Post by phoneman on Mar 10, 2019 15:35:32 GMT

I would like to be wrong, however, I believe that Sorby never intended the Pro Edge to sharpen tools, especially gouges, to any other profiles than the factory profiles. Sorby had the good sense to pay royalties to Tormek to use the Tormek SVD-185 gouge jig. Sorby also hired Jeff Farris, probably the greatest living expert on using the jig, and then Sorby let those possibilities just rot on the vine.

I attended a three hour Sorby seminar. The instructor was generally excellent, except for the gouge jig. He came up with some baloney about not being able to explain the gouge jig because of patent restrictions.

I think the Pro Edge has a lot of potential. It just looks like Sorby has abandoned it. How many years have passed since any improvements or new jigs were added? The Sorby staff can't even be bothered to support its own forum. Please prove me wrong; I hate to be pessimistic.

phoneman

Incidentally, Tormek redesigned the SVD-185 a while back. The new SVD-186 is much improved. Is Sorby still using the old model gouge jig with the hex wrench jig settings?

|

|

|

|

Post by sorbysharp on Mar 10, 2019 21:47:13 GMT

Thank you to Pete and phoneman (Bob?) for responding. This will help my demo a lot!

|

|

|

|

Post by phoneman on Mar 11, 2019 1:48:11 GMT

Sorbysharp,

Sorby (and Tormek) have both fallen into the same trap.Although Tormek has included more gouge configurations, both companies have striven to simplify set up to allow beginners to get good results. In many ways, I think this was a smart and practical decision. However, it leaves out some popular grinds, such as the 40-40 grind. The problem is that the engineer(s) who designed the jig have either passed on or retired. I do not believe either company has any current employees who have an understanding of the jig beyond the factory presets. This is especially limiting with the Pro Edge. That mostly limits more subtle use of the jig to users who are willing to invest time and tool steel in trial and error. (Hopefully those pioneering users will share their results by posting them on this forum.)

phoneman (not Bob)

|

|

|

|

Post by Pete on Mar 11, 2019 9:22:18 GMT

I would have to disagree with you there Phoneman, all of us with practice can freehand any grind angle and sweep, and once achieved maintaining it is easier than creating it. The whole point of using jigs is to limit the angles, to those that are of use to the job at hand, and make them fast and repeatable. most of my tools I have one of in a set of sizes, because I am an addict and I like tools... however ½" bowl gouges I have 3 all set to fingernail, but all at different angles for different depth of bowl. I have tried Ellsmere / Irish etc. but they don't suit the jobs and wood I use the most. I guess the difference is do you like sharpening tools in strange shapes, or do you sharpen tools primarily as a way to cut wood? if cutting wood is the goal then a limited set of angles and settings is the answer to quickly getting off the sharpener and back on the lathe. Both ProEdge and Tormek aim to achieve this. With ProEdge primarily focused on woodturning and Tormek more focused on general sharpening. You may like this:- www.yandles.co.uk/robert-sorby-proedge-long-grind-jig/p5748 I use it, but only on the fingernail setting, have tried and didn't like the longer grinds. My only criticisms of the ProEdge are:- it would have been very easy to include the Pro-set in the base of the machine rather than having a separate piece, and a rotating base would make it easier to use the leather strop, and back flattening mods suggested by Gus, but of course they are mods so Sorby wouldn't have been aware of the requirement. Plan to fix mine down to a custom made base with a lazy-susan bearing and 90 + 180 degree locking pin positions... but I also plan to re-make one set of storage units as roller cabinets to allow re-positioning of my router table, jointer etc. without lifting them, along with of course trebling the size of my workshop so that it can be 1/3rd of the size I need, and 3 x the size it is now! (don't tell the wife!) |

|

|

|

Post by phoneman on Mar 11, 2019 13:32:31 GMT

Pete,

You make a good point. Limiting the options definitely simplifies things. I think that's part of the genious of the gouge jig, very repeatable grind angles requiring a minimum of steel removal with resharpening. However, in the same way that benefits beginners and those who wants a more direct technique, I believe Sorby could pay more attention to users who prefer other grinds. This criticism applies equally to both Sorby and Tormek.

I can understand that Sorby might not have been aware of the 40 40 grind when the Pro Edge was first introduced. However, the Pro Edge has been around now for years. I have seen no evidence that Sorby has made any attempt to update or expand it. If the gouge jig cannot handle grinds like the 40 40, Sorby could offer some guidance for work arounds. The Sorby presenter who gave the seminar I took was quite competent. I am quite sure he could either figure out jig settings for some of the excluded grinds or give directions on how to freehand them with the Pro Edge. This would be a useful topic for a video. Again, I make this same criticism with Tormek.

Tool users expect more today. I believe the Pro Edge is up to the challenge when used in skilled hands. I have not seen Sorby staff keeping up with today's sharpening demands. I take no pleasure in stating this, and would be delighted to be wrong.

phoneman

|

|

|

|

Post by phoneman on Mar 11, 2019 15:36:30 GMT

Pete,

I do not mean to sound negative or overly critical with Sorby. I have always been pleased with the quality of my Sorby tools. Sorby remains my first choice brand with turning tools. However,

If I was dispatched to install or repair a telephone or data circuit for you, you should quite reasonably expect me to make every effort to complete that task completely and in a timely manner. I would expect the same high level of service from you if you were working on my computer or computer program. Neither of us would accept being ignored.

I expect that same level of service commitment from the Sorby staff. Ever since I started following the forum stats, I have never seen any evidence of a Sorby staffer logging in. Checking the forum for new posts takes less than a minute. Most days there are no new posts. I expect a Sorby staffer to log in and out twice every working day. I don't expect this on weekends or holidays. If a question is posted after close of business on Friday, I do not expect a response before Monday morning. I do expect a response on Monday morning. I expect spam to be eliminated by Monday morning. If the staffer will be on holiday for an extended period, I expect the staffer to arrange for coverage by another staffer. Sadly,I have not seen this.

I think we deserve better than this.

phoneman

|

|

|

|

Post by phoneman on Mar 12, 2019 19:13:11 GMT

Nick, Returning to your original question, does your gouge jig control the jig settings with a hex wrench or a plastic locking screw? (In Tormek terms, is it the SVD-185 or SVD-186?) Glenn Lucas discusses the differences in the two models in one of his newer videos. With the older 185 model, Glenn used to use several jigs, each permanently set for one particular gouge because of slippage. The ratcheting locking system of the 186 solved the slippage problem. (Glenn now uses just one jig for all of his gouges.) If, for example, jig setting #3 is not enough for your desired grind and jig setting #4 is too much, you might be able to tweak your jig into jig setting “3 1/2” plus or minus. Leave this jig as a dedicated jig for this grind. Purchase another one for your other gouges. Use a very fine tip marker to mark witness marks for your customized setting. This slippage may work to your advantage. You could also use the old Tormek marker trick turning the wheel (or belt) by hand to see where the marker is being removed to get you close. I used the same fine tip marker on a blank piece of label tape in the slots of my TTS-100 to set projection lengths for chisels and planes. (It speeds up my Tormek......although I have not yet broken the speed of sound with it.  ) Sorry I did not think of this sooner. phoneman |

|